Die Cutting Machines: Key Features and Benefits

These are special tools created for the purpose of cutting different shapes and sizes using various materials. This machinery significantly simplifies the process of cutting out unusual patterns - any shapes, letters and merge ruins without handwork that may be time-consuming on top.

How Die Cutting Machines Assists Making Of Products

Die cutting machines are very much needed for the factories and businesses that needs to create a considerable amount of products and on war footing, too. Think about a factory that needs to produce thousands of stickers or labels. These types of machines assist in cutting materials such as paper, fabric or leather rather than the traditional way (manual method) which is to use scissors. Which means that companies can devise products for stickers, labels and packages in much less time than it would take with manual doing. This agility is critical to enable organizations keep pace with customer demands and stay ahead in the market.

The Pros of Die Cutting Machines

The use of state-of-the-art technology makes it possible for die cutting machines to produce a neat and clean cut every time. A die is one of the essential components in the machine and like a blade it shears through materials. Dies can be a fun thing - they can be changed out so you are able to make different shapes/sizes of this. This means that all cuts will be the same, ensuring a clean and professional end result. Consistency - Your products must be the same every time, a good reputation need consistency and customers want to know what their getting.

Why the Die Cutting Machines Are Important

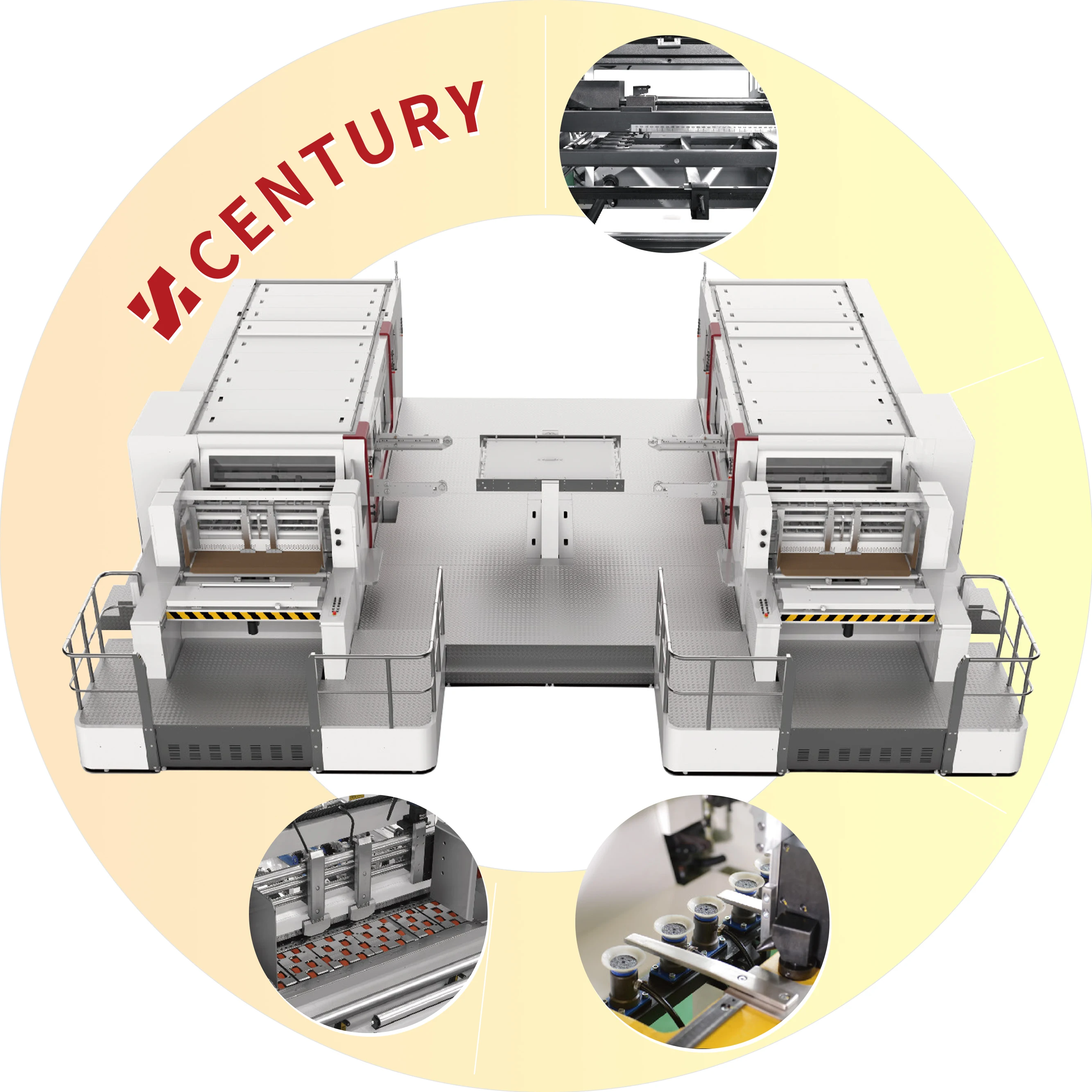

Versatility - The most obvious advantage with a die cutting machine is that it can cut lots of different types of materials. Paper, cardboard, leather, fabric and foam can all be sliced with these. That is why they are used in a variety of industries, such as manufacturing business card marketing and packaging. As these machines are available in different shapes and sizes, one can easily customize the same to suit specific requirements of diverse industries. Clearly, that means whether you're producing something large like a sign or tiny little pieces for an arts and crafts set Die Cutting Machine can help you do it fast.

Die Cutting Machines for Perfect Cuts Every Time

Proper cutting in any product counts a lot. Cutting: With a die cutting machine, the process of cutting is inches wider and specific as compared to scissors; since when you operate with this type of apparatuss all areas apply equal stress on their respective blades. This allows the blade to readily cut through the material with consistent precision, creating identical pieces that are all of equal shape and size. And this is a precision which has helped reduce waste because it allows materials to be used wisely. If you have textures or details that are much more intricate and delicate, a Second hand die cutting machine is the easy way to go about it instead of struggling with your regular scissors.

Best Features of Die Cutting Machines

If you are trying to decide on a die cutting machine, it is essential that you carefully consider the feature set which will best accommodate your production requirements. Find Some Main Features to Check in a Dedicated WordPress Hosting

Design-specific dies: The machine you buy should come with the facility for custom die designing. Great for when you have a wacky idea. This is available in many different shapes and sizes of dies to suit your work requirements.

Efficiency- The die-cutting machines are believed to be one of the fastest. BenefitsThey will be able to help you make more products in less time. Quick processing means that you can send your items to the customers as fast as possible which in turn is beneficial for boosting up of business and taking it onto a more successful path.

User-friendly: When you are a newcomer it is one of the most significant things to get yourself any such machine that can easily be operated. Some machines can be too complex, but there are some who strive to keep it as simple and understandable for its users. The best type of machine is one with a detailed user manual that you can refer to, or you have scientific support from whom the manufacturer when there are problems.

Many Designs: The die cutting machines can make many shapes You make labels, shapes and letters or decoration. There is so advanced machines through the help of which we can cut fabric or leather that are quite helpful in fashion industries and textile as well;

Safety features: Last but not least essential function of Semi automatic die cutting machine is that these must contain safety facilities to provide security. These features can range from safety switches to emergency stops. The bottom line is that with designate of safety feature in machines it confirms the security for everyone who are working around them and those to be penetrate into safe surrounding.

Comments

Post a Comment