Understanding the Functionality of Toilet Paper Machines

We all understand, how important hygiene is in day to day life and keeping ourselves clean as a part of this process. One thing that aids in keeping us clean is tissue papers. Even though we use it everyday, have you ever wondered how is toilet paper made? It's a fascinating process! Learn how machines that create toilet paper function and what makes the work to fill our bathrooms.

Why Toilet Paper Machines Are So Important

This modification in how we produce toilet paper has been achieved through the mechanism of a tissue-paper machine. These amazing Toilet Paper/Kitchen Towel Machine Series make the toilet paper, free of germs which is a necessity for our health. They also do a good job of keeping the toilet paper soft. Thereby enabling countries to make large amount of toilet paper in an easily accessible and not too expensive manner. This will make this critical product available to all, keeping people safe and clean.

Technology's Part in the Production of Toilet Paper

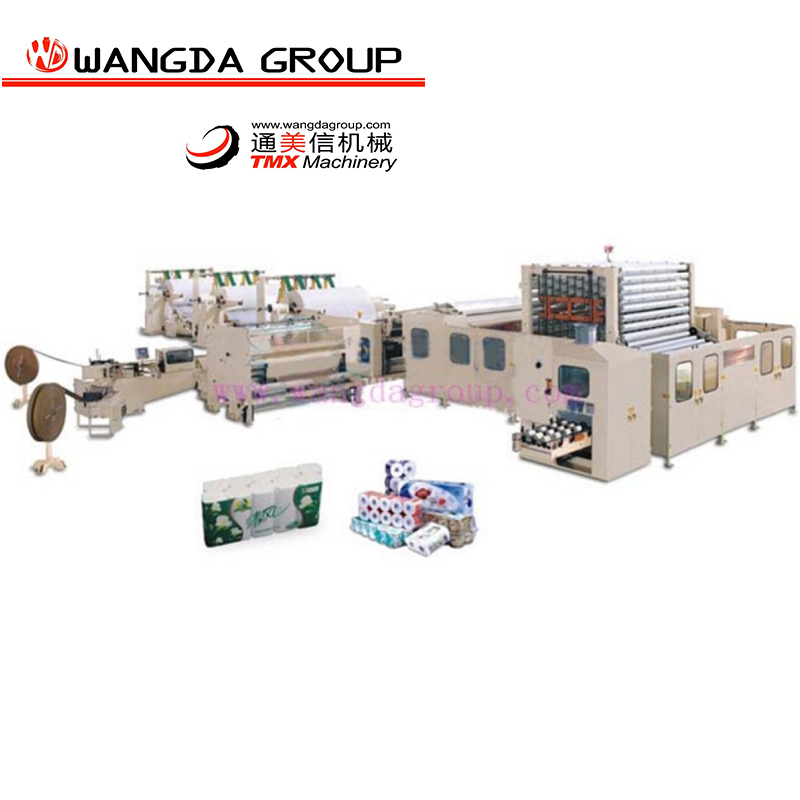

Toilet paper machines combine technology and engineering to produce good quality toilet papers. It begin from the raw material, fresh pulp taken out of trees or to recycle paper that has been used in many other things. All of this is done by machines, which makes everything faster and more efficient. First, starting from unrolling the big roll of paper upto cutting and packing final product which we all see in malls.

Using specifically engineered technology, these Toilet Paper Rewinding and Perforating Machine monitor each of the steps along this process to ensure that their toilet paper reaches optimal quality. Toilet paper has become more quickly produced, a more reliable product able to be created and is also better for our environment due in part, thanks to this technology. Our rolls are made locally which means that we can ensure quality, and deliver them to your homes in a much shorter amount of time while also protecting our planet.

How Toilet Paper Is Made(step by step)

The process of making toilet paper with this machines is very simple and consists mainly from the following key steps; Key components of the Toilet Paper Band Saw Cutting Machine are unwind stand, embossing unit, perforation unit, rewinder stands and log cutter. It started with unrolling the huge roll of paper and then heavily pressed to make it soft enough you won't get irritated while using it.

The embossing unit is essential as it gives the toilet paper a unique pattern that creates an enjoyable sensation on use. Next, the punching unit punches holes through paper. It actually has those holes that let us to rip one of perfectly the right length for whatever we are trying to use it with. After that is completed the toilet paper rolls are rolled up into smaller sized lXnegiven length and cut so they can fit onto our bathroom holders.

Maintaining Tools as Clean Suitable

If we want the toilet paper machines to perform well, in daily life, we must maintain and care for them properly. These machines are exceptionally complex and come equipped with numerous moving parts, one of which breaking or malfunctioning will bring the hemorrhage process to a grinding halt. This may cause delays and also reduce the availability of toilet paper for everyone.

More Maintenance = Longer-Lasting Machines And Higher Efficiency Is paramount in the toilet paper world where time kills you. Maintenance to consist of cleaning the machines, adding oil for smooth operation and replacing any worn out parts. Because they are keeping the machines in good repair, these operators (do) their part by making this paper for a long time and we can always use this essential product when needed.

What's Next for Toilet Paper?

The toilet paper industry has experience a rapid shift and more people are showing concern with using recycled products in order to protect our planet. That has led people to wonder: how can they create toilet paper from something old - or otherwise cut down on waste? Due to new technology, improved machines can now be built in a way that is more environmentally friendly and even make high-quality toilet paper more efficiently.

Comments

Post a Comment