Mastering Collector Ring Technology: Turbocharging Turbines

Fine-Tuning Collector Ring Technology: Turbines on Steroids

Turbines are key machinery across many industries, aiding in the improved functioning. Turbine Collectors: Importance of the Collector Ring This crucial component is responsible for both collecting valuable data as well as sending power to the turbine which improves overall performance. Innovation in collector ring technology has continued unabated over the years and it is an essential aid to be able best utilize a turbine. This article will serve you well in understanding the advantages, innovations, safety precautions as well as uses and application specifics of collector rings to stake your claim on mastering this technology.

Benefits of Collector Ring Technology

There are many advantages to collector ring technology. A major advantage of this is that it increases the efficiency and output power in turbines. The collator rings take the power in and out of a turbine, controlling how it performs to do just that. They also ensure a stable voltage supply and power transmission to the turbine as well.

Plus, collector rings are proven to be reliable and longer last. Made of strong materials such as graphite and copper, they can withstand harsh environmental situations that make them long-lasting. These parts have a few, rare maintenance cases saving costs and time with no need for regular visit for repairs.

Advances in Disconnect Collector Ring Technology

Significant innovations have occurred in collector ring technology over the last few years. Of major significance is the way it has become possible to integrate fiber optic However, a specific milestone in data transition could be collectors and that have seen all their capabilities transformed! This allows for direct transmission of information in real time and the absence of electromagnetic interference is minimized to prevent signal degradation; resulting in more precise detection, collection & delivery.

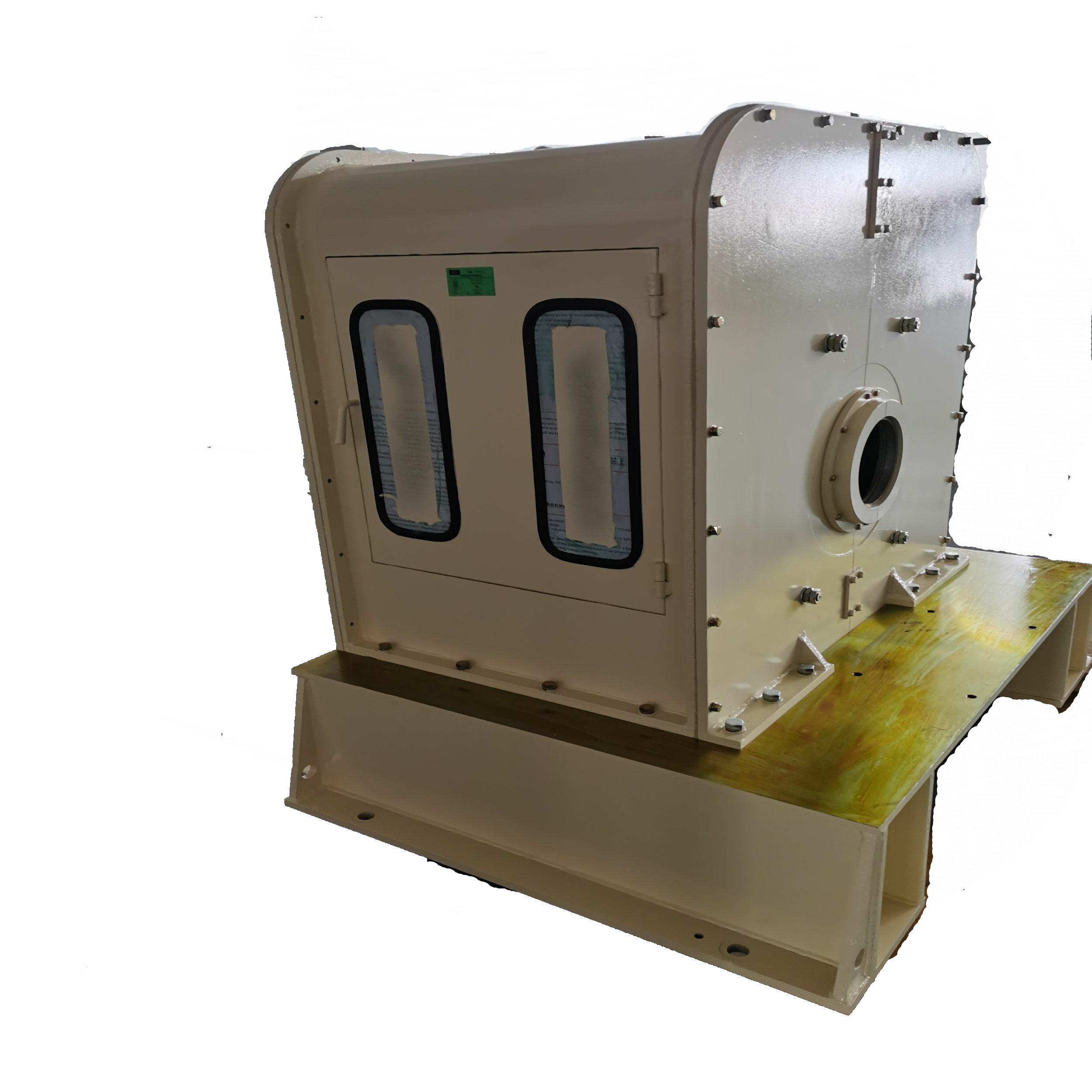

A further more advanced step is the creation of collector rings for use in harsh environments such as high temperatures, corrosive atmospheres and high pressure ENVIRONMENTAL CONTROL SYSTEMS - The last design contains by enlarge ENVIROMENT CONTROLE SYETEMS 3. Specialized rings that are made with more sophisticated designs and materials to withstand the elements, handling wear-and-tear as well allowing it to work without fail under harsher conditions.

Collector ring technology safety

The collector ring technology must be implemented in a safe manner, making safety the number one priority. Manufacturers take more quality care in the engineering and construction of these components to prevent problems that could cause electrical failures, lead to data loss or even present safety hazards. This makes sticking to strict safety measures and codes all the more important in order to protect anyone working near collector rings.

Collector Ring Technology Applications

Collector ring technology has many applications, from gas and steam turbines to wind turbines and electric generators, as well a variety of industries including military equipment (such as UAV's), space exploration industry while medical equipmentRouting brush solutions can be applied in combination with collector rings for optimal performance. This data is vital for turbine performance and longevity, and the sensor rings are how it gets collected.

Using Collector Ring Technology

Process in collector ring technology The collector ring is originally mounted inside the turbine's shaft or in an external casing. In this sick state, the collector ring is used to pass power and data from one side of the bearing system to a remote control system that throws all manner of codes when things are breaking because before they fully do so in public you can handle it.

Collector Ring Technology Maintenance and Service

In order to maintain the minimum potential and life of collector ring technology, it is important that proper maintenance schedules are followed. Routine maintenance of the collector ring includes visual inspections and also a cleaning as necessary to keep down carbon and oxidation that can cause friction rubbing, wear. All of our fleet tires must be maintained to stay in operation, and nothing more obviously needs maintenance than the bustier components of a vehicle.

Manufacturer Standards of Collector Ring Technology

Collector rings are an important part of every commercial slip ring, and high-quality collector ring technology will maximize performance as well as reliability. Collecting rings are available from various manufacturers with different qualities of material, design and manufacturing processes. High-end collector ring technology offers turbine owners higher efficiency, less downtime and long-term savings to the bottom line.

Comments

Post a Comment