The Future of Turbine Efficiency: Innovations in Collector Ring Technology

Collector rings are very important part of the turbine systems which make them to transfer electrical power between stationary and rotating parts. Put simply, they provide the electrical power required to drive the rotating components of a turbine machine. One part does not move, while the other rotates and thus ensures that electricity flows in a ring. In addition, collector rings are used to transmit signals for monitoring and controlling any systems of the turbine machinery.

Rewards of Using Collector Rings In Turbine Systems

Collector rings provide many advantages in turbine systems. In the first place, it is because that they are capable of transmitting electrical power very well and thus reducing flowing resistance to guarantee steady running of turbine unit. Collector rings are designed to have a low brush contact resistance, which helps to make this system particularly efficient. Additionally, collector rings are non-interfacing components in the turbine system. They also produce no electromagnetic radiation, which means that they will not the disturb other electronic components of turbine machine.

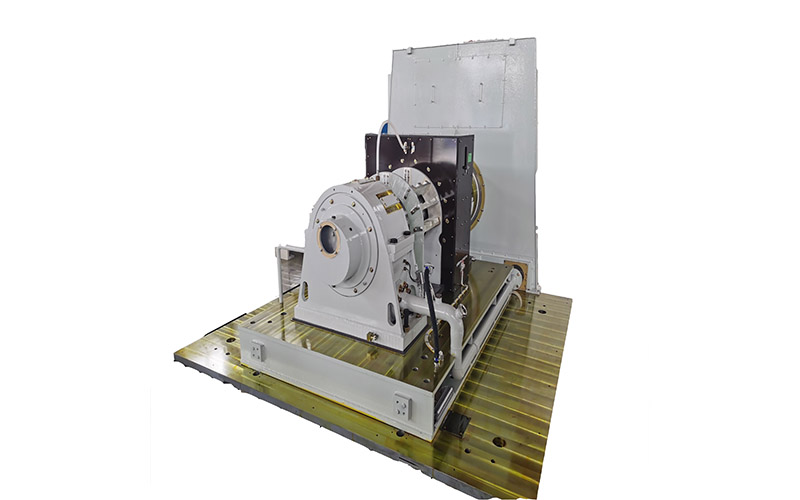

Modern Collector Ring Technology with Unique Functions and Safety Precautions

The new generation of collector rings have incorporated things like smart tech for safety improvements. These collector rings (mounted on a swivel) are also made of the highest-quality materials-like carbon fibers and silver alloys-to handle high temperatures, extreme operational pressures. This strength must remain through the turbine machines to ensure their believed efficiency. The latest sealing technologies are used to keep away dust, water, chemicals or even contaminations from the machinery of turbine guise being operated in areas which causes disruption.

How to Efficiently Use and Maintain Collector Rings for Turbine Systems

Correct installation processes are required for the appropriate use of collector rings in turbine systems. Regular cleaning and maintenance of collector ringsis crucial to ensure a long lifeand the best performance. These units should receive regular inspections to detect any signs of damage that may necessitate immediate repair or replacement. This means that the first step of cleaning will be dealing with all harmful materials, like dirt or dust. In addition, it is important to check the electrical contact resistance of collector rings by performing tests.

Reason for using collector rings in various applications of modern industries

Collector rings are an important component of a number of contemporary industries such as power generation, mining and transportation. In the power generation space, collector rings deliver power from steam turbines, hydro turbines and gas turbine plants to service generators. The mining collecting ring is used in large excavators and all heavy machinery acting on electric power. Collector rings are also parts of trains and the wind turbine, as well as some amusement park rides because they help in delivering electricity to their rotating elements.

Comments

Post a Comment